ADT-HC8200 High-end Gantry type CNC Cutting Controller | £2340.00 plus VAT

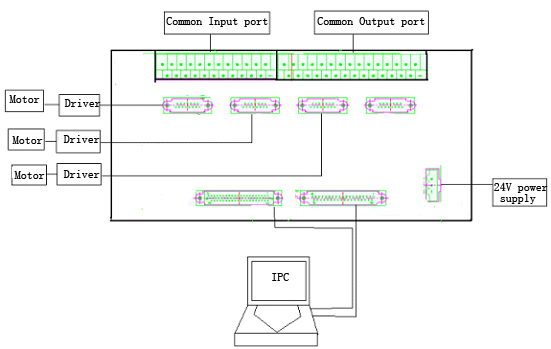

The ADT-HC8200 is a new high-end gantry type CNC Cutting Controller. The unit has passed CE and ISO certificates and adopts Inter Atom low power CPU Processing Cores. With industrial computer (IPC) & Windows operating systems, these units are both flexible and adaptable.

£2340.00

Prices are NOT inclusive of VAT

- Windows operation system;

- IPC (Industrial computer) processor core;

- Multi-language compile, supports CAD, DXF file transformation;

- Perfect process for plasma/oxy-fuel cutting/ plasma mark/ powder-spraying laying out;

- Kerf, gas compensation function;

- User friendly operation interface; editable graphics library;

- The breakpoint memory function: supports sudden pause process memory, alarm & power off memory;

- Product Configuration:

- CPU: Intel(R) Atom(TM) CPU N270 @ 1.60GHz

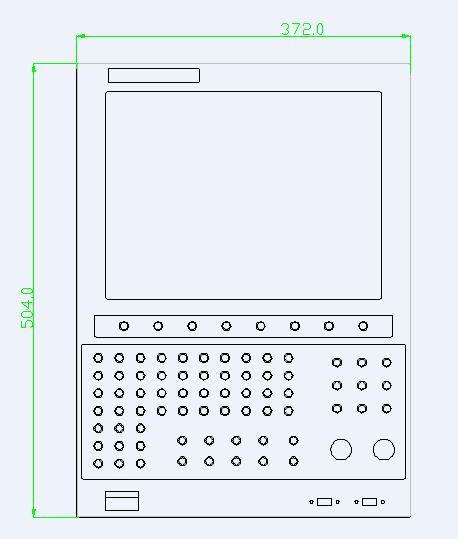

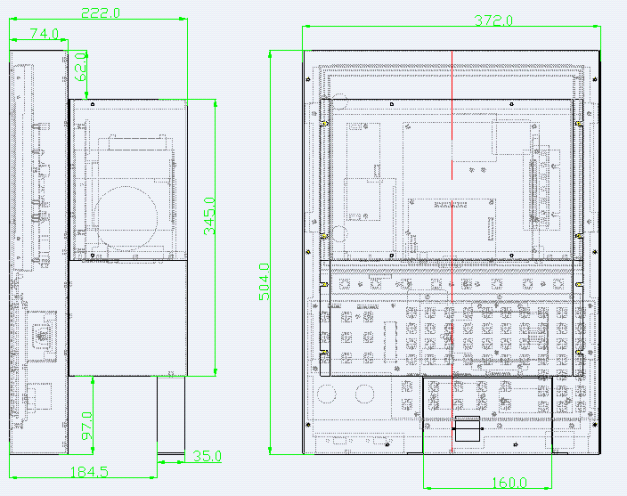

- Display (all-in-one machine): 15 Inch industrial LCD colorful display screen

- Storage & Hardware: 1GB;16G, CF card

- USB: USB2.0

- Keyboard: industrial keyboard

- Case: Steel Structure

- Power: PS/2 standard, ATX Power,300W, AC 220 Input

- Interface Board Power: 24V

- Max. pulse frequency: 1HMZ

- Components:

- Electronic Box + Control Panel + Screen Display+ Data line + Connector

- 2-4 Axis step/servo motor control CNC cutting Controller;

- Window Operation System, Multi language compile;

- Compatible ISO-G code and ESSI Code;

- Kerf, gas compensation function;

- Free set for plate steel area;

- Pause, continue, breakpoint & power failure memory, backward, forward and other practical functions;

- The breakpoint memory function: supports sudden pause process memory, alarm & power off memory;

- Hand/Auto optional operation for ignite, gas, cutting gas, plasma torch height, preheat gas, arc stick, perforate etc;

- Auto-return absolute zero function, relevant zero setting function;

- Calibration functions for cutting parts;

- Real time Display: current coordinates, control status & speed real-time display;

- Radom control speed of Acc/Dec & Corner Intelligence ACC/DEC in the process of cutting;

- Supporting time memory: Reminding time for change spare parts;

- Diagnosis function, help users to solve machine failure quickly;

- Support graphics library;

- Support touch screen, standard PS / 2 and a USB mouse, keyboard;

- Work Conditions:

Work Conditions | ||

Temperature | Work | -5℃~50℃ |

Storage transport | -30℃~70℃ | |

Relative Humidity | Work | 20%~90%(℃) |

Storage transport | 10%~95%(℃) | |

Atmospheric Pressure | 86Kpa~106Kpa | |

Power supply | AC 220V | |

Power | 300W | |

Consumption | 300W | |

- Gantry type plasma/oxy-fuel cutting machine

- Plasma maker

- Powder-spraying laying out